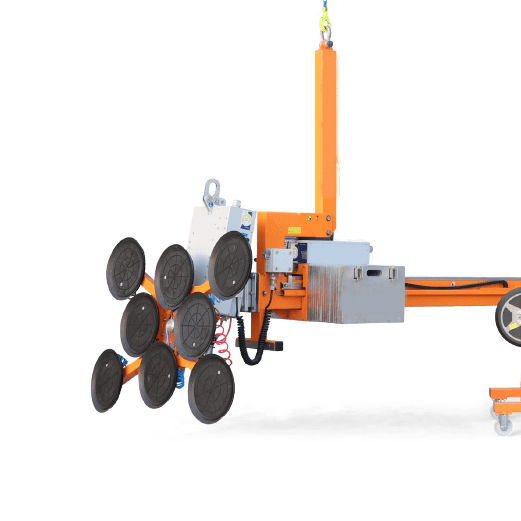

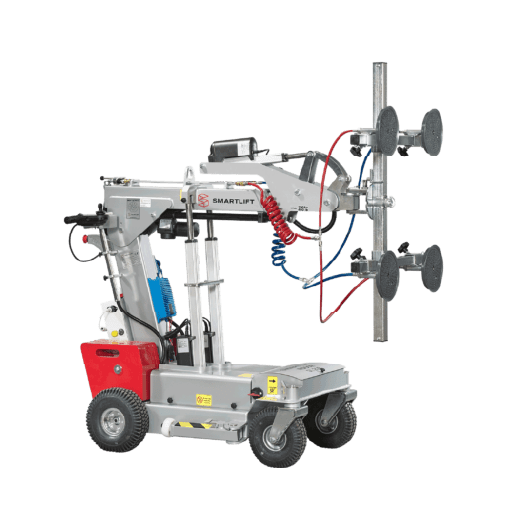

Wirth GL-M1200: Innovative Glass Lifter for Flat and Curved Glass

The Wirth GL-M1200 is the latest model in Wirth's glass lifter series, with a maximum capacity of 1200 kg. This powerful lifter is equipped with strong suction pads capable of handling both flat and curved glass with ease. Thanks to its multiple configuration options, it is perfectly suited for a wide range of applications.

The GL-M1200 features radio remote control, allowing for fully electric rotation and tilting. It also comes equipped with a practical blow-off function.

Wirth GL-M Series: Powered Movements for Ultimate Precision

Glass lifters in the Wirth GL-M series feature powered movements, enabling:

-

endless 360° rotation,

-

and 90° electric tilting.

Glass panels can be locked in any position using the radio remote control, ensuring precise and controlled façade construction.

Advantages of Choosing a Wirth Glass Lifter

-

Double operational safety

-

Precise glass positioning

-

Minimized risk of breakage

-

Reduced installation time

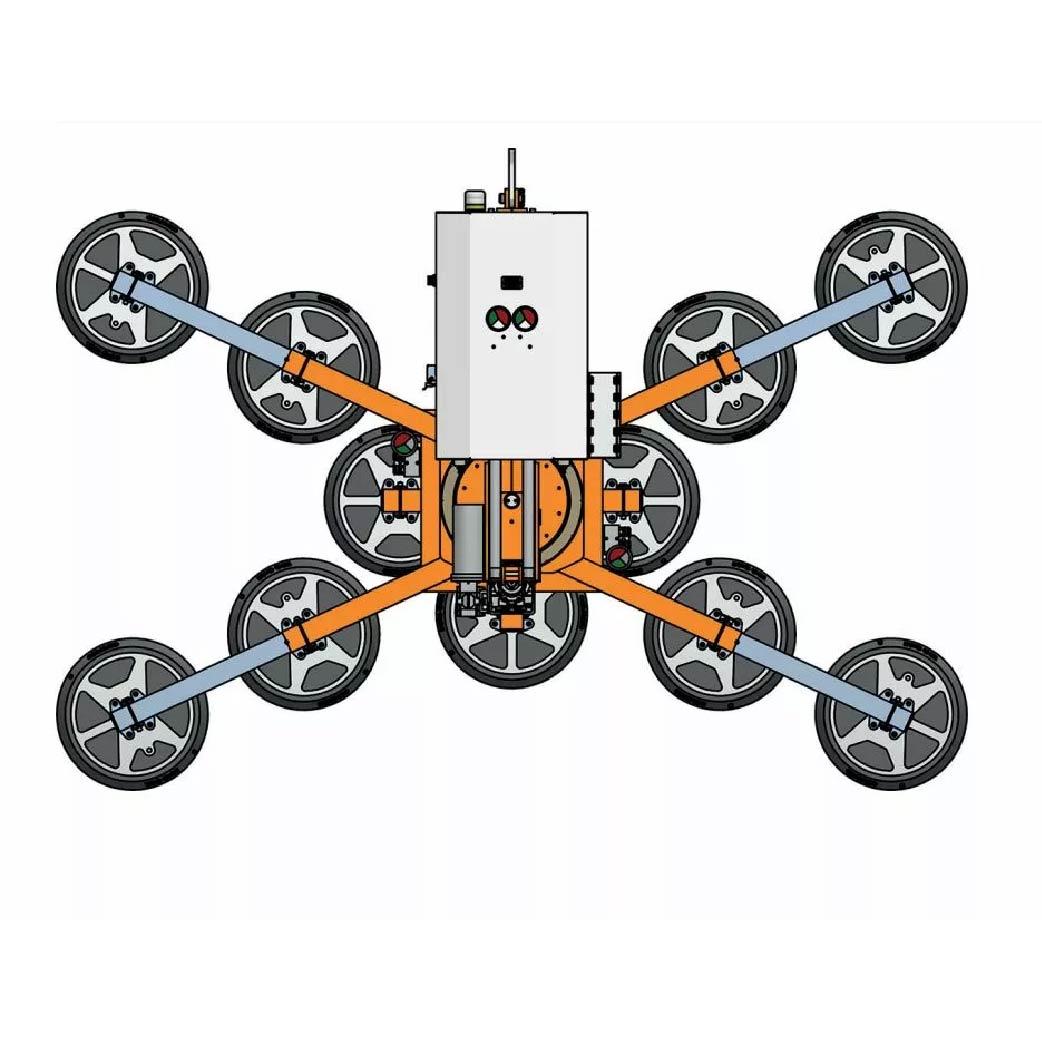

All Wirth glass lifters come with a dual vacuum circuit, meaning:

-

check valves

-

vacuum reservoirs

-

pressure regulators

-

vacuum gauges

-

and suction pads

are duplicated. Each vacuum circuit is color-coded (blue and red).

The lifter is ready for use only when both circuits have reached sufficient vacuum. Two integrated vacuum gauges constantly display the actual vacuum levels.

Wirth GL-MF1200

Technical specifications

Downloads

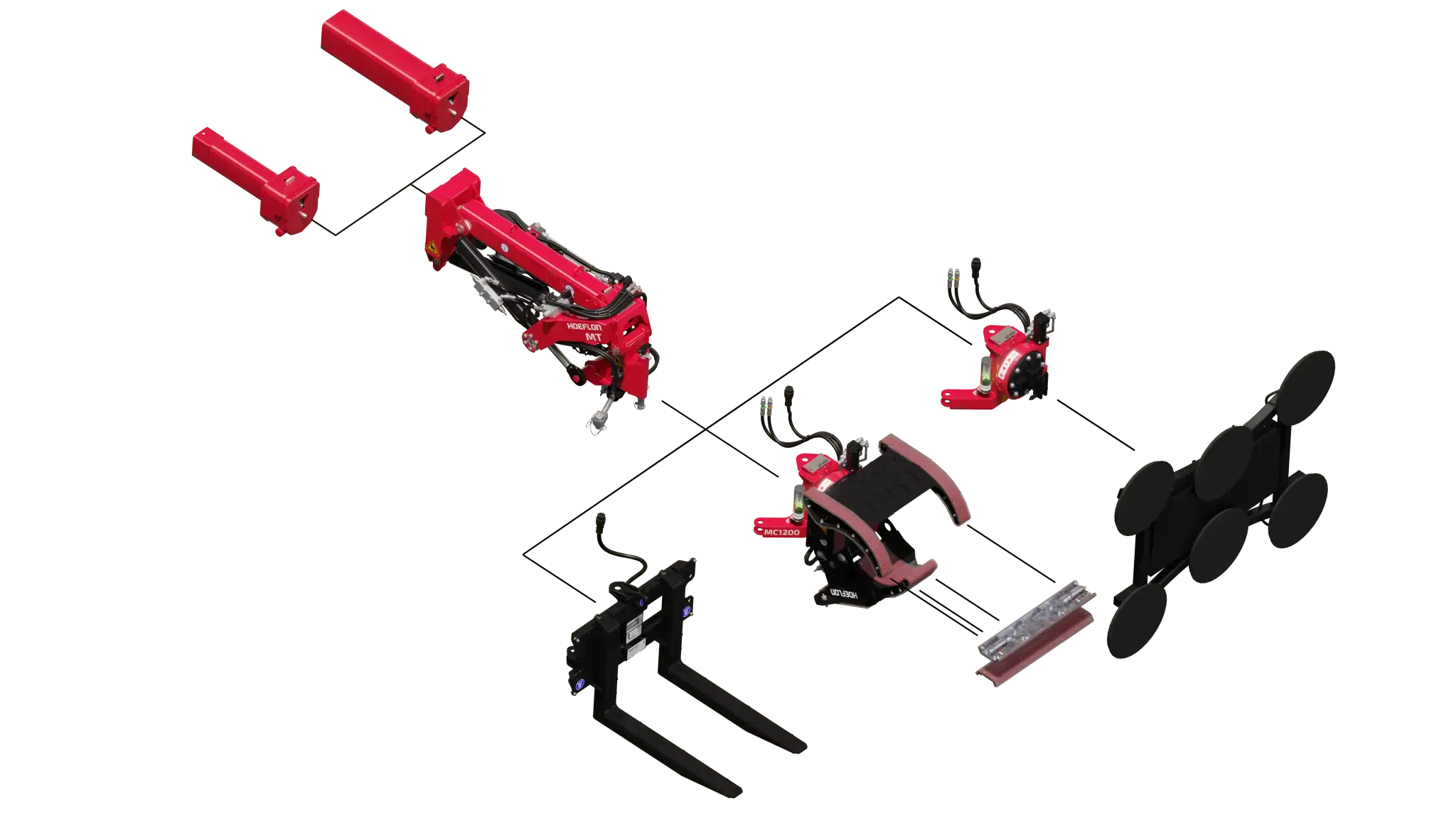

C-hook 750

What is a C-hook?

A C-hook is a lifting device in the shape of the letter “C,” designed for safely and efficiently lifting loads such as glass plates, metal coils or other heavy objects. The design allows for lifting loads in situations with limited space or obstacles, such as roof overhangs or facades.

Applications of C-hooks

Glass installation:

C-hooks are often used in combination with vacuum lifters to hoist glass panes over obstacles and precisely position them during façade installation.Coil handling:

In industrial environments, C-hooks are used to transport metal coils.Limited space:

Due to their shape, C-hooks are ideal for use in restricted areas where traditional lifting gear cannot fit.

Features

Shape:

The C-shape allows for lifting without the hook obstructing the load.Capacity:

C-hooks are available in various capacities, ranging from a few hundred kilograms to several tons, depending on the model and manufacturer.Material:

Typically made from high-grade steel for strength and durability.

Technical properties

Capacity

750 Kg

Own weight

85 kg